Take every mother-in-law joke you ever heard, the good, the

bad and the ugly, and wrap them all up in a 4’ 2” package, throw a piece of

ribbon around it and you will have my mother-in-law.

My mother-in-law is one tough cookie. She survived loosing

her mother at 6-years of age, being orphaned at 10-years of age, loosing all

her brothers, sisters, nieces and nephews, as well as aunts, uncles and cousins

after being transported to Auschwitz at 16-years of age in a cattle car, jumping

off of trains getting out of Europe after the war to ensure her future sons

wouldn’t become part of the Russian Army at 20-years of age and she survived

raising my wife for the rest of her life. God bless her for it and I love her

to death because of it, but damn, she can become one angry bull when anyone

doesn’t do what she wants.

My father-in-law was the family’s forth generation to enter

the painting profession, his family’s business doing everything from fresco

ceilings to exterior house painting. In Europe, to become a painter back then

meant a five-year apprenticeship learning to do everything from making your own

paint to graining. Having lost all but one brother and his sister to the camps,

his family home and business destroyed, he didn’t argue when his new wife told

him she wanted to leave for places yet decided. When he finally hit Canada, he had

a second shock; the profession he held near and dear wasn’t respected here the

way it was in Europe, something he still doesn’t understand to this day. Past

destroyed and pride wounded, he picked up his brushes and rollers and went to

work with the rest of the painters. While he never gained the same stature he

had at home, he worked himself up the chain and started to earn a fair living

for his family.

By their tenth anniversary of arriving in Canada, the old

man was making enough money to allow his wife to start

decorating…well…everything.

Now I’m not saying she did it single-handedly, but if you

ask any of the old fabric hawkers, they will tell you that there was a

worldwide shortage of green velvet material back in the mid-1960’s, and it

caused quite a commotion. That was the same year my mother-in-law started

decorating her home.

In her livingroom sits a couch that, she proudly likes to

tell anyone who will listen, is the first king-sized pullout bed ever made. Now

a king-sized mattress is roughly 80” square. You then have to have room for the

mechanism and then the arms are added outside of that. So while she is proud as

punch of that couch, the reality is, the damned thing is 2” shy of 8’. It has

to be the biggest couch I have ever seen. As with all manufactured products

built prior to the late 70’s, this manufacturer didn’t skimp on the gauge of

the steel, so the damn thing is as heavy as it is long, probably weighing in at

250-pounds, if it weighs an ounce.

Added to the 3 ½-square miles of green velvet fabric that

covers this thing is a low-back easy chair, a matching love seat and six

diningroom chairs, all, you guessed it, covered in green velvet. But it doesn’t

stop there.

When I first came on the scene, the walls were covered with

embossed wallpaper that reminded me of the doilies that my grandmother had on

all the arms and backs of her chairs. If the design wasn’t bad enough, it was

done in some sort of short, green fuzz that, to my mother-in-law’s eyes, looked

like green velvet. This, of course, using those same eyes, made this paper a

perfect match for the furniture. I’ll tell you, I am lucky I suddenly became

comatose during that first visit, because if I hadn’t, I would have run

screaming from the place and would have never got to marry my wife, who, I will

mention, hates anything made of velvet - in any colour - with a passion – thank bloody God!

Married to a painter, my mother-in-law wasn’t shy about serving

him up a busman’s holiday, insisting that he repaint often. The first time around

for the “green” rooms, off they went to order more of the same paper. The old

girl was dashed when they told her that the paper was no longer in production.

My father-in-law, bless his heart, took it on himself to carefully steam the

paper from the walls, cleaned all the glue off the back of each piece, rolled

each one up and when the painting was done, re-hung it. He did this, not once

for her, but twice. The second time he damaged enough paper that there wasn’t

enough to do both rooms and hallway, so the hallway got painted an “almost

matching” green. He still says the paper was getting brittle with age, but I

think the crafty old bugger tore the stuff on purpose because he was tired of

looking at it.

The beloved paper might be gone, but the sea of green velvet

still exists. When they moved into their new abode she drove me nuts pushing me

to try and arrange that furniture in the in the same arrangement that they had

been living with for these last forty-three years. Because the layout of the

new wasn’t anywhere near the layout of the old, it was impossible to do exactly,

but I got it as close as I could.

Now you would think she would be happy, wouldn’t you. Here

she is, 70-years older than she ever expected to be, living in a nice condo

high over the city, in reasonably good health and surrounded by her furniture

and nick-knacks. Nope.

The other day I noticed that her livingroom drapes were

closed all the time so I asked her about it. She told me she couldn’t open

them. I thought there was something wrong with the rod, so I went to look and

found nothing, the drapes moved, as they should, and as I’m a glutton for

punishment, I went back to her and reported this. She told me that she could

open and close them herself, just fine thank you very much, but she couldn’t

open them because then she would see the drapery rod.

Now this took me off guard, seriously off guard. The rod was

new, and was an exact match to the old one in the old place. I know this

because I had purchased and hung it myself; taking this upon myself because I

felt the 40-odd year old one was yellowed and worn. I then honestly thought she

was joking, and even chuckled. Oh, boy. Wrong, wrong, wrong, wrong thing to do.

Her eyes flashed black and this small, frail, four-foot nothing woman suddenly

appeared to tower over me.

Seeing that I had royally pissed her off, I tried logic,

asking why, after forty-odd years she suddenly didn’t like the look of the rod.

I think you can categorize that as mistake number two. I spent the next ten

minutes trying to convince her I didn’t think she was crazy as it was obvious,

now that I took a second look at it, that this new rod was completely different

than the old. It wasn’t. It was the same style and worked exactly the same way,

but I had a much better chance of convincing her that it was my mistake than I

did convincing her they were the same. I left shortly afterwards defeated.

For the rest of that afternoon I thought about what I could

do for the old bird so she would open her drapes again and get some sunshine in

their lives. Whatever it was, it had to be something I could make as, if I did

that, I knew all would be forgiven.

I did get an idea, but there was a catch. It involved

bending some small pieces of wood.

I had steamed a lot of wood when I replaced the bottom of my

boat; so bending wood wasn’t new to me. My problem is that I didn’t have a

steam box or a place to use it if I did, so just before dinner than night, I

tried something else; something I had read about, but never tried.

I filled my wife’s stockpot almost to the top with water,

added a little rock salt and set it on the stove to come to a boil. I went into

the office and dug out some scraps of oak; 3/8” by 1 5/8” by 12”. When I had

trimmed them equal, I threw them into the pot. I then returned to the office to

make a mold.

I let the wood cook for about an hour, pulled them both out,

and with my wife doing the deed with the clamps; we clamped them both together

around the mold.

Once I had devised a mount that would take my mother-in-law’s

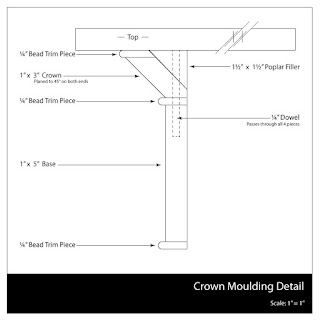

abuse, here’s what I came up with…

I have them finished with four coats of varnish, ready to

install tomorrow. They will mount under the windowsill and will allow the two

panels of drapes to be connected in the middle and be “swaged” to each side.

This is how it will mount and work…

I know this isn’t a faithful reproduction of George

Washington’s potty-chair to you guys, but to me, it is huge. If there is one

thing I hate more than green velvet, it’s “swaged” anything, especially drapes.

After these get installed, every time I walk into that room I’ll have to face

those droopy drapes and know that I did it, with protest, but I still swaged

those damned drapes.

Awe, well. Its Christmas, and these just might bring a

smile, and hopefully a little sunshine, onto the old girl’s face.

And with that, I wish all of you nothing but health,

happiness and good fortune throughout this coming new year.

Peace,

Mitchell